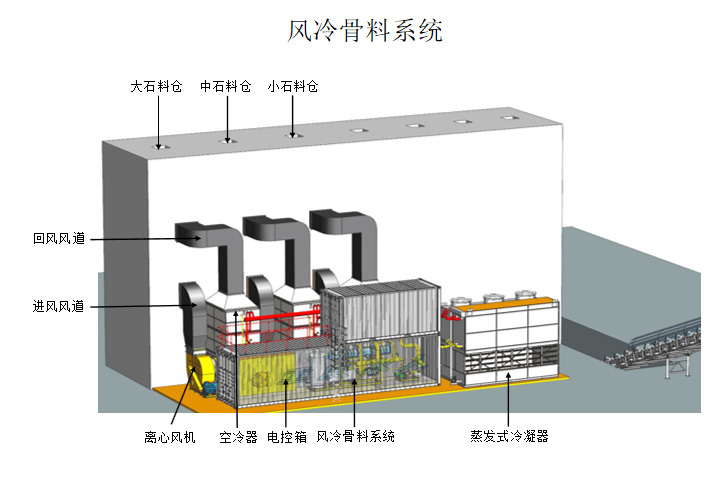

Air-cooled aggregate system

Category:

Details

● During concrete pouring, ice and chilled water are used to lower the concrete's discharge temperature. However, in large-volume concrete pouring, to ensure pouring quality, aggregate pre-cooling is usually required using an aggregate air cooling method to ensure a lower discharge temperature (below 14 degrees).

● Aggregate air cooling works on the principle that air is cooled by an air cooler and then sent into the aggregate bin by a centrifugal fan to cool the aggregate in the bin.

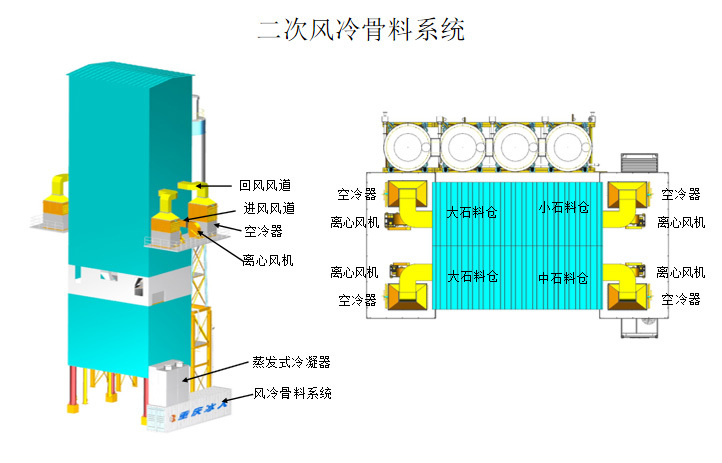

● The characteristics of aggregate air cooling are that the aggregate can be continuously cooled in the material storage bin of the mixing building, with cold air flowing from bottom to top (or horizontally) while the aggregate flows from top to bottom at the material usage rate. The process is simple and easy to operate.

● Aggregate air cooling is divided into primary air cooling (ground aggregate bin) and secondary air cooling (mixing building storage bin).

Features of Aggregate Air Cooling Products

● The aggregate air cooling host adopts a modular design, with all components integrated into a container that has a dust-proof, rain-proof, and constant temperature system.

● The clean environment inside the container ensures reliable operation of the PLC system.

● Pipelines are completed in the factory; only a small number of pipelines need to be connected on-site.

● On-site modular assembly shortens on-site construction time.

● Small on-site footprint, easy to transport and relocate.

Main Parameters of Aggregate Air Cooling Unit

| Host Model | Cooling Capacity (kW) |

Evaporation Temperature (°C) |

Condensation Temperature (°C) |

||||||||

| G1 | G2 | G3 | G4 | G1 | G2 | G3 | G4 | ||||

| ZJ-580 | 460 | -6 | 35 | / | / | / | 2300 | / | / | / | 48195 |

| ZJ-710 | 557 | -6 | 35 | / | 2700 | / | / | / | 71971 | / | / |

| ZJ-830 | 652 | -6 | 35 | / | / | 3500 | / | / | / | 46267 | / |

| ZJ-2-830 | 1020 | -13 | 35 | / | 2000 | 2600 | 2600 | / | 27780 | 48500 | 48500 |

| ZJ-2-1270 | 1674 | -13 | 35 | / | 3500 | 5100 | 2100 | / | 27780 | 67400 | 48500 |

| ZJ-4-710 | 1598 | -15 | 38 | 2400 | 2400 | 1400 | 1300 | 8700 | 8700 | 55800 | 55800 |

| ZJ-4-930 | 2560 | -11 | 40 | / | 2×2800 | 3900 | 3400 | / | 48862 | 67483 | 69570 |

● The following parameters need to be provided by the customer during model selection calculation: climate conditions in the project location in recent years, concrete mix ratio, production strength, bin size, discharge temperature, etc.

Main Technical Parameters of Air Cooler

| Item | |||||||||

| GKL2000 | GKL1800 | GKL1600 | GKL1400 | GKL1200 | GKL1000 | GKL800 | GKL600 | GKL400 | |

| Evaporation Area (m²) | 2000 | 1800 | 1600 | 1400 | 1200 | 1000 | 800 | 600 | 400 |

| Fin Spacing (mm) | 16-8 | 16-8 | 16-8 | 16-8 | 16-8 | 16-8 | 16-8 | 16-8 | 16-8 |

| Defrosting Water Volume (t/h) | 70 | 65 | 55 | 50 | 45 | 35 | 30 | 20 | 20 |

| Defrosting Water Pressure (MPa) | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 |

| Windward Area (m²) | 7.5 | 7.2 | 6 | 5.8 | 5.6 | 5.4 | 5.2 | 5 | 4.8 |

| Airflow Area (m²) | 1.8 | 1.7 | 1.4 | 1.3 | 1.2 | 1.1 | 0.9 | 0.8 | 0.7 |

Application Pictures

Flake ice machine Chilled water machine Air-cooled aggregate system

Other Products

I want to consult

During your browsing of our products, is there anything that you find particularly satisfactory or that needs improvement? Your inquiries or suggestions will directly help us improve product and service quality, bringing you a more intimate experience.

* Please fill in the above fields (* indicates required fields), and we will reply to your feedback as soon as possible.